VALEMO has been performing visual inspections of wind turbine blades on its customers’ assets for almost ten years. Our experience in this field has led us to carry out these inspections on most types of wind turbine. With the objective of increasing our skills, we wanted to develop a new technical service in the field of visual inspection by drone.

So, at the end of last year, we decided to invest in a drone to carry out :

- Blade inspections, particularly on certain types of turbine where the rotation of the blades allowing all four sides to be seen could only be done by climbing into a nacelle.

- Nacelle inspections.

- Tower inspections.

- Foundation inspections, particularly for offshore applications.

We had to choose a partner to train our remote pilots and provide the drone with its accessories. The drone selected is a DJI M300 RTK. It’s a multi-purpose drone that can be equipped with a variety of cameras, from a daylight camera to an infra-red camera.

The advantages of using a drone are :

- To be able to acquire data on site in a limited amount of time (around 30 minutes/wind turbine).

- Autonomous data acquisition.

- Comfort for the technician carrying out the mission, as the equipment can be deployed quite quickly.

The disadvantages are :

- Mission preparation time (compliance with civil aviation regulations, checking equipment updates).

The course

Four technicians were selected to receive drone pilot training.

The practical training took place over three weeks at two of the sites we operate in central France: the Angerville wind farm and the Mézières photovoltaic power station.

The technicians came away from the training fully satisfied and highly motivated to begin their first on-site assignments.

Theoretical training took place alongside practical training on a dedicated web platform, with several multiple-choice questionnaires to obtain the CATT (Certificat d’aptitude télépilote de drone), which is essential if you want to be able to fly a drone in a professional environment.

How the inspection works

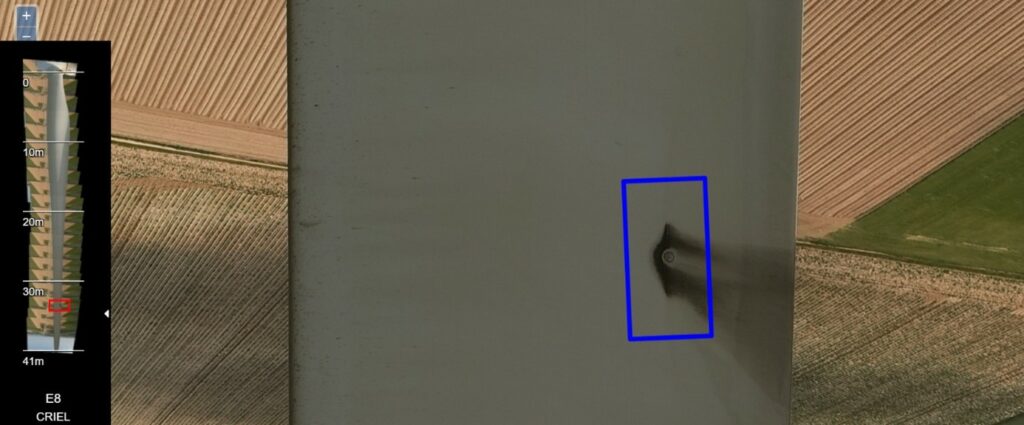

To be able to take photos of the wind turbines, the remote pilot has to stop the turbine. He locks the rotor and positions the blades in the anti-Y position. We then use an application supplied by our partner to carry out the flight automatically.

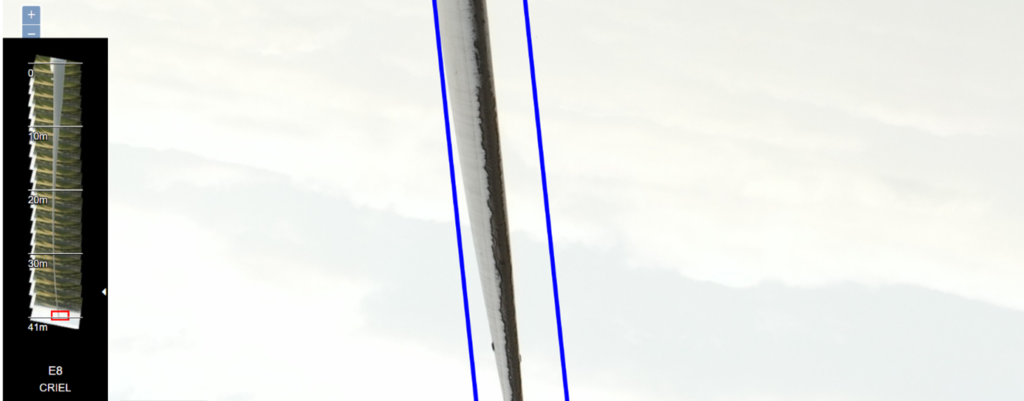

The data is sent to our partner on a server for processing in order to reconstruct the four surfaces of the three blades of each wind turbine. Our two blade experts then take over to analyse and categorise the faults. Finally, they issue reports that the services coordinator sends to the customer.

The advantage of using this tool is that we are more competitive, since the downtime of the wind turbine is shorter. Moreover, the photo quality is similar, if not better, than with other tools.

Frist inspections

Our first newly qualified telepilot made his first acquisitions at the Criel-sur-Mer wind farm in Normandy.

It was a complete success for him. He was able to clock up his first flying hours for VALEMO.

Partners

We are supported by partners recognised for their expertise in data processing (CORNIS) and (OIM) for advice and training.

Developments

Our four remote pilots hope to develop the business by offering new services such as thermographic inspection of photovoltaic power stations, measurement of lightning path continuity on wind turbine blades, visual inspections of hydroelectric power stations and off-shore inspection.