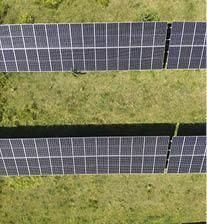

Thanks to drone data acquisition by VALEMO technicians and the use of an advanced analysis platform, the performance of photovoltaic power plants can be optimized over the long term.

Rigorous methodology for reliable results

Our drone inspection process is based on several key steps:

- Preliminary analysis: study of the technical context and the customer’s specific needs, integration of plans and verification of the regulatory framework governing the flight.

- Flight parameterization: precise definition of parameters to ensure optimum coverage.

- Inspection: systematic quality control of collected data to ensure completeness and image clarity.

- Data processing: transfer to our specialized analysis platform to create a digital twin of the power plant.

- Defect identification and prioritization: automatic characterization by algorithm, verification by an expert, then classification according to severity and impact on performance.

- Results: delivery of a detailed summary report, providing a clear, usable overview of the anomalies detected.

The benefits of our approach

- Fast, efficient geographic coverage

- Easy access and safety

- Precise fault detection according to industry standards (IEC TS 62446-3)

- Detailed geo-referenced data that can be traced over time

Anticipating under-performance means that minor faults can be rectified quickly, reducing downtime and optimizing production.

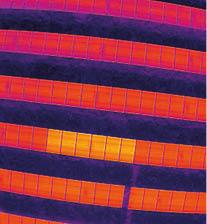

Examples of faults detected

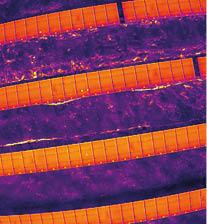

Shade detection

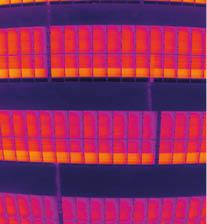

Hot spot detection

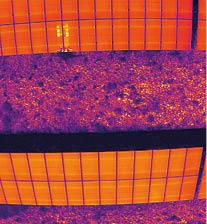

Vegetation shading

Open chain

Why us?

At VALEMO, our technicians specialized in renewable energies guarantee high-quality inspections and diagnostics, thanks to their mastery of market technologies and their expertise in control and electricity. With 15 bases across the country, we ensure optimum responsiveness close to the installations.