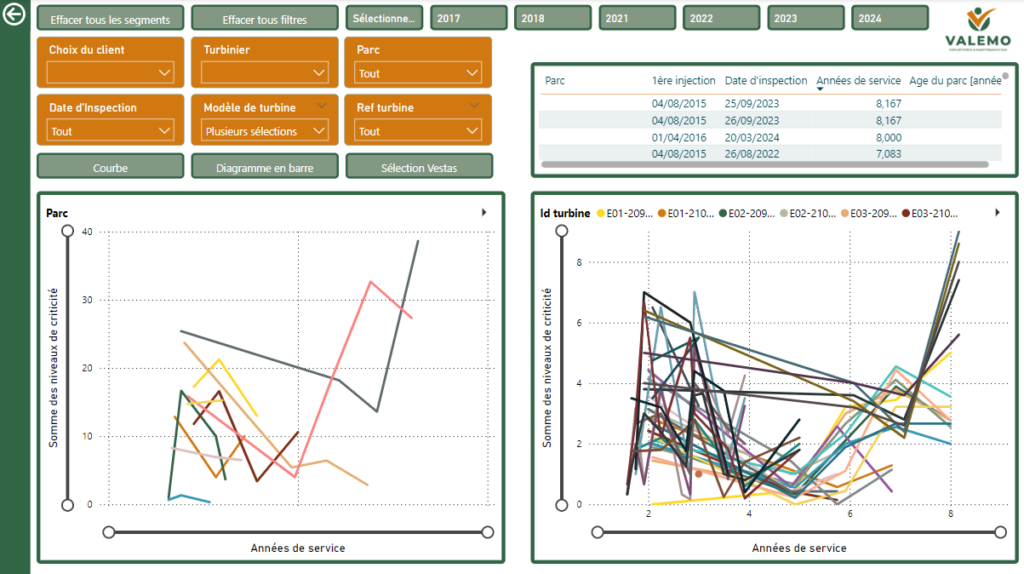

In the summer of 2024, our technical audit experts carried out an in-depth study of blade defects identified on a fleet of 10 wind farm projects comprising a total of 50 wind turbines. To carry out this study, a tool was developed to analyze all the defects observed during blade inspections carried out on site by our technical support staff over the last ten years, so as to be able to compare projects with a view to identifying abnormal trends.

The aim of this study was to analyze the importance and evolution of defects classified into 3 main categories: erosion, structure, lightning.

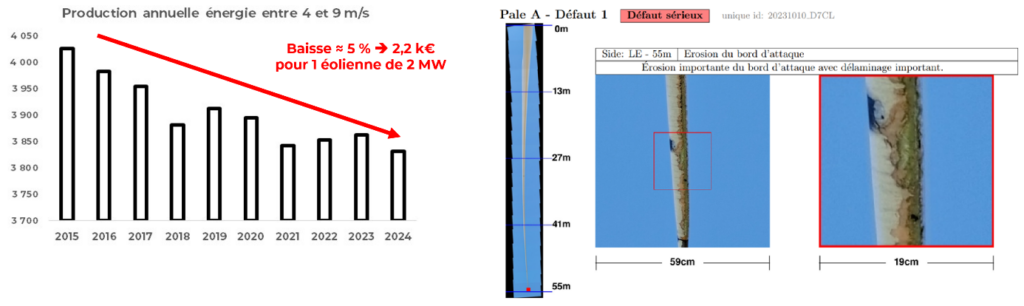

The results enabled us to determine the order of magnitude of production losses due to erosion problems (see figure below). The measurements also made it possible to precisely identify structural defects, which may be due to a problem with the design of the blade, as well as defects linked to lightning strikes, which may be due to a failure of the lightning protection system, the cause of a significant loss of earnings.

This study has enabled us to draw up a blade maintenance strategy by linking these different types of defect to the players involved: erosion is more a question of wind turbine operation, while structural and lightning defects are more a question of contractual relations with wind turbine suppliers.