With the increasing digitalization of critical infrastructures and the multiplication of players as well as data needs, particularly in the energy sector, cyber security stands out as top priority.

The implementation of the European directive NIS2 (Network and Information Systems Directive 2), aimed at strengthening the security of networks and information systems, now imposes a strict regulatory framework on operators of essential services.

In this context, installation of firewalls on energy production sites becomes a crucial issue to protect these sensitive infrastructures.

Why install a firewall on your renewable power plants?

1. Connecting all players

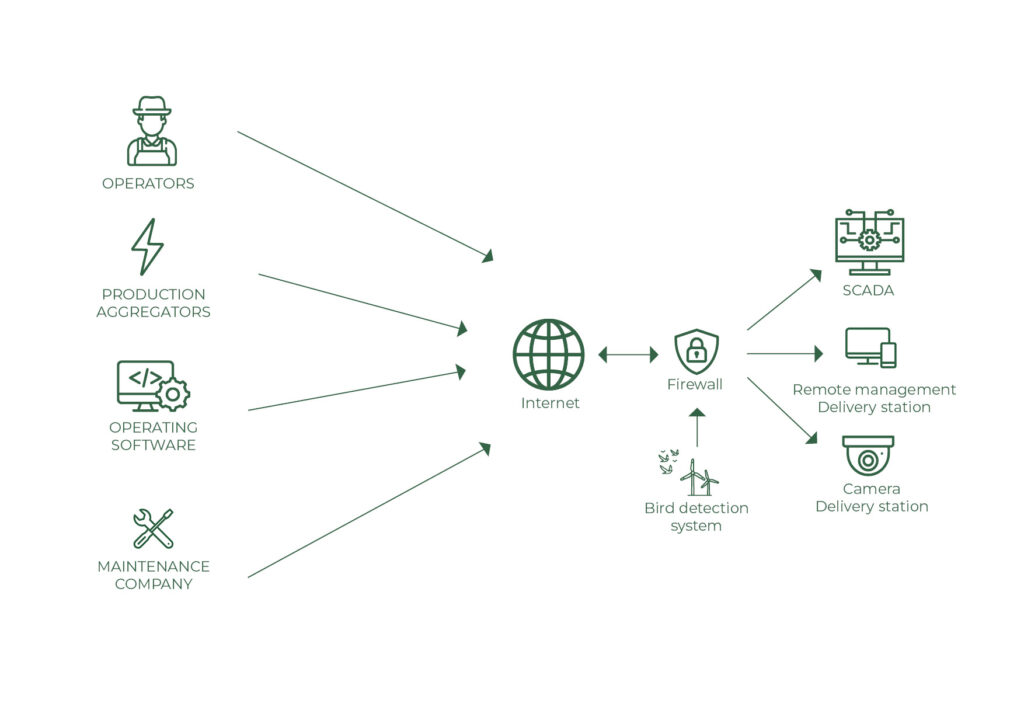

In less than 10 years, the numbers of actors connected to energy production sites has increased considerably (ex: direct seller, bird dynamic curtailment, operating software, operators, maintainers, etc.). Installation of firewalls allows both to create these technical accesses but also to secure them.

2. Protection of data and critical systems

Energy production sites use control and automation systems, often connected to external networks. Firewalls play a crucial role in filtering incoming and outgoing traffic, protecting sensitive data and critical operations from unauthorized access.

3. Threat Prevention and Mitigation

Critical infrastructure, such as power plants, are prime targets for cybercriminals. Firewalls, as a first line of defence, help prevent attacks, reducing the risk of operational disruptions that could have serious consequences, including the shutdown of power production for an indefinite period.

4. NIS2 regulatory Compliance

The NIS2 directive imposes strict security measures to protect networks and information systems. The installation of firewalls becomes an essential step to comply with this regulation. For electricity production sites, this approach is no longer simply a technical requirement, but a strategic necessity. By securing critical infrastructures, firewalls contribute to the continuity of services, the protection of national security, and compliance with legal obligations.

Why trust VALEMO for firewall installations?

Due to its role as a power plant operator and the internal development of its data analysis tools, VALEMO has been confronted with these issues of connectivity and cyber security since 2008.

| As of January 1, 2025 | Number of firewalls installed | Forecast for 2025 | |

| Energy production sites | Wind power plant | 109 | 38 |

| Solar power plant | 18 | 61 | |

| Hydroelectric power plants | 18 | 0 | |

| High voltage substation | Poste HTB | 3 | 0 |

| Total | 148 | 99 | |

We have already worked with most of:

- – Wind turbine suppliers

(ACCIONA, ENERCON, G.E., GAMESA, NORDEX, SENVION, SIEMENS, VESTAS, etc.), - – Bird dynamic curtailment suppliers

(Biodiv-Wind, Sens Of Life, etc.), - – Solar inverter suppliers

(SMA, SUNGROW, POWER ELECTRONICS, SCHNEIDER, HUAWEI, etc.), - – Substation automation suppliers,

VALEMO, with over 15 years of experience and collaboration with the main suppliers in the sector, is a recognized expert in securing renewable energy production infrastructures. The installation of firewalls, essential to meet the requirements of the NIS2 directive, is a strategic priority that VALEMO fully masters, guaranteeing network security, regulatory compliance and continuity of energy services.