Since 2023, VALEMO has been developing its expertise in the field of technical inspections using drones. These inspections are used to detect faults and take measurements on renewable energy power plants to ensure that they are operating at optimum efficiency.

- Visual inspection of wind turbines and PV thermography with the DJI M350 drone

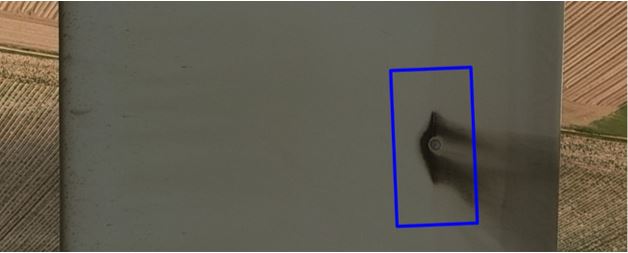

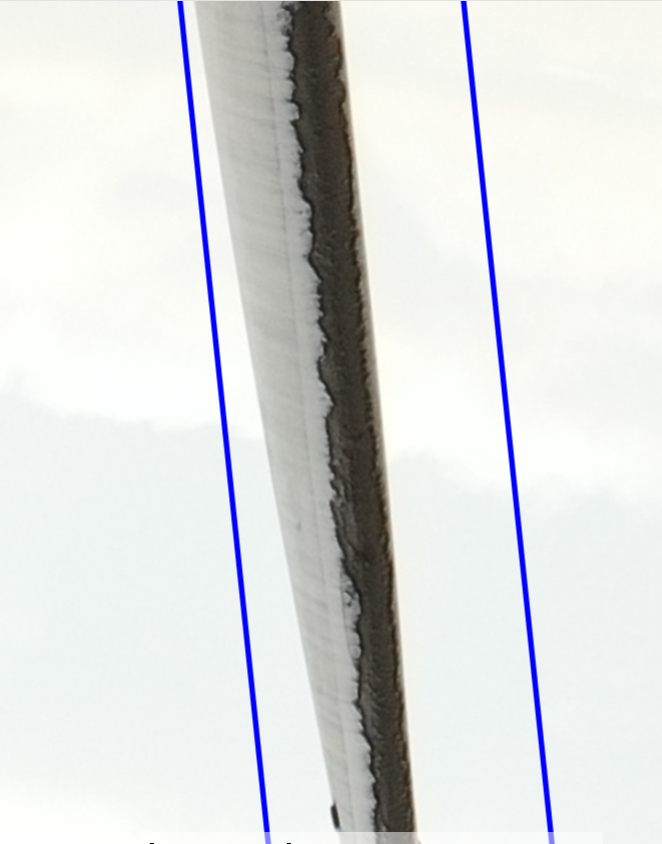

We carry out visual inspections of blades, nacelles, towers and foundations on onshore and offshore wind turbines using the high-quality P1 sensor, which produces highly accurate images.

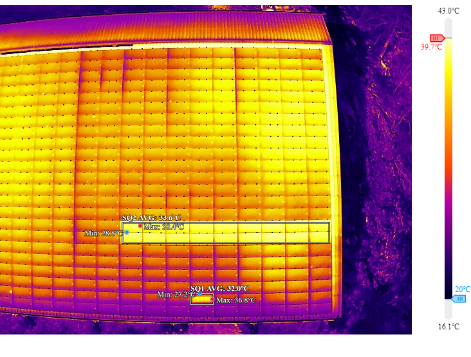

We also carry out infra-red inspections on photovoltaic power plants using the H20T sensor, which is also of very high quality.

These two sensors are mounted on a DJI Matrice 350 drone, which is a benchmark on the market for industrial inspections.

- Wind turbine electrical continuity measurement with the DJI M350 drone and the VOLTA system

We carry out electrical continuity measurements on lightning protection systems in order to check the integrity of the equipment, but also to meet the regulatory requirement of the ICPE decree, which specifies in Article 9 that a continuity measurement must be carried out once every two years to check the continuity of the earthing system. This obligation is based on the recommendations of standard IEC61400-24 (lightning protection).

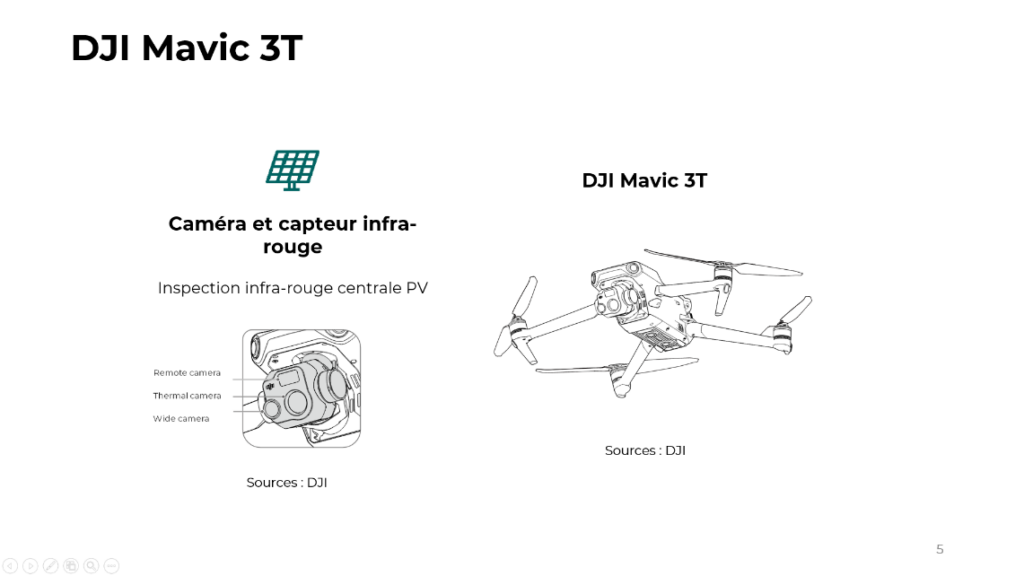

- PV infrared measurement with the DJI Mavic 3T drone

Finally, we also carry out infra-red inspections of photovoltaic power plants using the DJI Mavic 3T drone.

- Advantageous solutions for our customers

These drone-based technical inspection solutions enable us to detect faults that could compromise the proper operation of installations, and to meet regulatory obligations, particularly in the case of measuring the electrical continuity of wind turbines. The logistical resources deployed are under control, ensuring that on-site risks and costs are kept under control. As a result, operating costs are kept under control and energy production is optimised.

- VALEMO, a partner of choice

Unlike the majority of remote pilots, our remote pilots are very familiar with the installations and are therefore able to intervene effectively and independently. What’s more, as an integrated player in the operation of projects, the technical inspections carried out by VALEMO form part of a more global framework that enables us to make better use of the results to correct any faults that are found.