Since 2018, VALEMO has implemented SCADA data analysis with the aim of optimising wind turbine performance and maintenance. This tool identifies various faults, such as an anemometer or temperature anomaly, underperformance, PLC wind drift, misalignment, as well as cooling and lubrication issues.

To anticipate and rectify these performance problems, SCADA data analysis follows a five-step process:

- Data acquisition : The data generated by the wind turbines is collected and transferred to the analysis tool.

- Data processing: The data is filtered and evaluated to ensure that only relevant, high-quality data is retained.

- Data analysis: This phase involves the use of indicator calculations and artificial intelligence algorithms to detect anomalies and faults.

- Diagnosis: VALEMO’s teams draw up a detailed report characterising the wind turbine’s performance and identifying any problems.

- Personalised support: VALEMO provides personalised support, helping its customers to interpret the results of the analysis and advising them on the actions to be taken to improve the performance and maintenance of their wind turbines.

Our independent analyses provide an objective assessment of performance by correlating or comparing the results with those of the turbine manufacturer. We offer improved operational monitoring by providing a clear view of the state of the machines, particularly when there is a change of operator or the warranty comes to an end, while ensuring constant monitoring of temperatures. Our analysis aims to maximise production by avoiding or correcting under-performance and unplanned maintenance, thereby helping to ensure that wind farm assets operate at optimum reliability and reduce production losses. We offer personalised support, helping our customers to interpret the results of the analysis and advising them on the actions they need to take to improve the performance of their wind farms, ensuring that they make informed and effective decisions.

Case study: identification of an underperforming wind turbine (before/after)

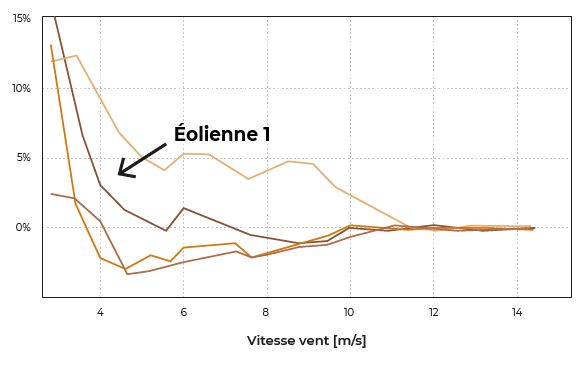

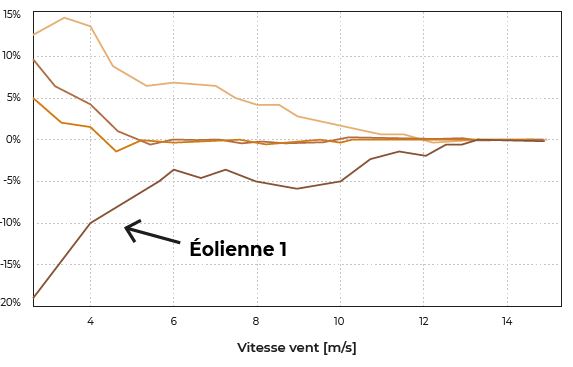

Analysis of deviations from the median power curve for 4 wind turbines

Wind turbine 1: significant deviations at low wind speeds

>Potential misalignment of the turbine in relation to the wind direction

• LiDAR measurement campaign

• Confirmation of an alignment problem

• Re-alignment of the wind turbine

>Production gain >15%