Since 2018, VALEMO has been performing SCADA data analysis to improve the performance and maintenance of wind turbines.

This tool allows the detection of faults such as anemometer and temperature anomalies, under-performance, wind drift, misalignment or also cooling faults and lubrication faults.

How can SCADA data analysis anticipate and correct these performance failures?

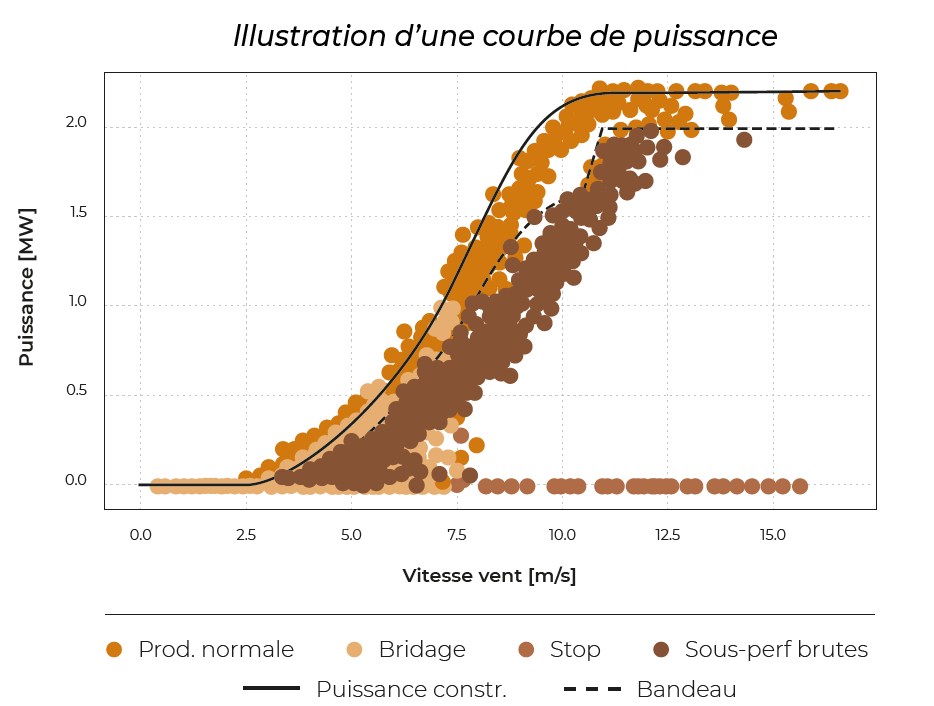

SCADA data analysis is based on an analysis of the power curve of the deliverable, the production and the deposit. Our teams then analyse and verify the clamps, and perform calculations and monitoring of performance indicators. Then, our teams then carry out statistical and shape analysis of the power curve. VALEMO completes this analysis with a monitoring and conditional maintenance of the main components of the wind turbine by observing the temperatures.

The SCADA data analysis is carried out in 5 steps:

- Data acquisition: The data provided by the wind turbine will be transferred into the tool

- Data processing: The data will be filtered and qualified to keep only the coherent ones and then evaluate their quality

- Data analysis: This analysis is performed with indicator calculations and anomalies will be detected thanks to artificial intelligence

- Diagnosis: Our teams produce a detailed report and characterise the performance

- Tailor-made support: VALEMO assists its clients in interpreting the results and in choosing the actions to be implemented